abstract

A common complication of diabetes is neuropathy, which is nerve damage that typically leads to loss of sensation in the feet and is a major cause of foot ulcers and leg amputations. A key limitation to current screening and ulcer prevention in India is the impracticality of current diagnostic equipment, which is expensive, bulky, and requires trained operators. Consequently, the majority of the Indian diabetic population in low-resource settings is currently not being tested for neuropathy.

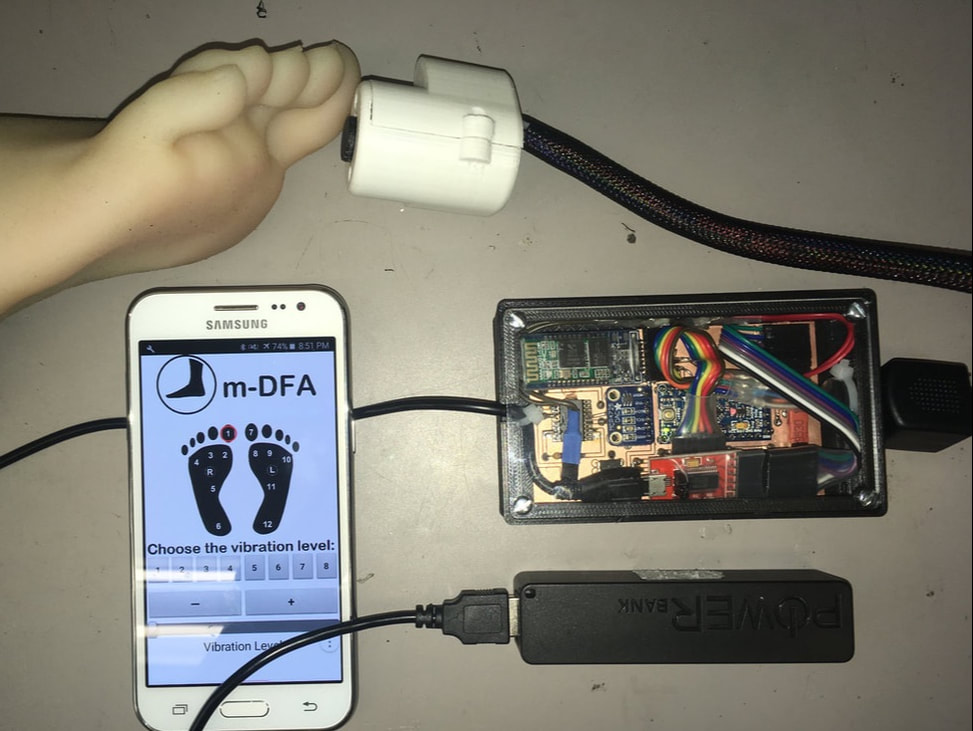

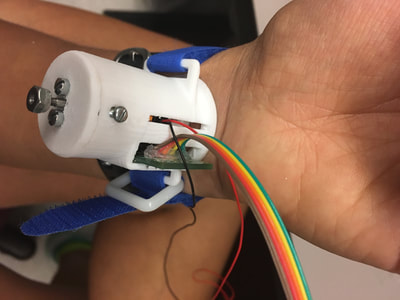

The Mobile-Enabled Diabetic Foot Analyzer (mDFA) is a portable neuropathy screening device that provides quantitative information about a diabetic patient’s touch sensation in the foot. It connects wirelessly to a mobile phone or tablet, which can record sensation levels and track changes over time.

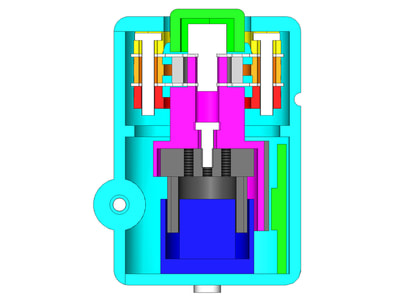

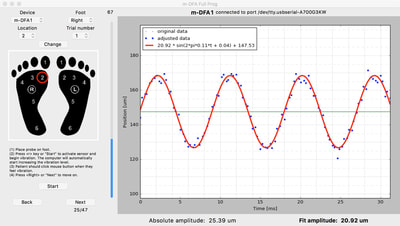

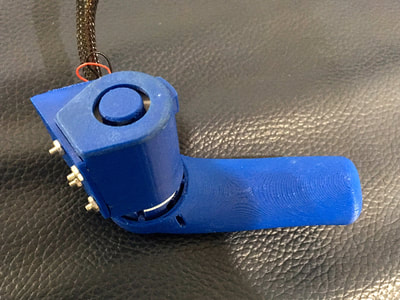

The m-DFA evaluates a person’s nerve function by determining the Vibration Perception Threshold (VPT) at a given point. VPT is defined as the lowest intensity of vibration that a person is able to feel at the application location. A probe, which vibrates at a fixed frequency of ~100 Hz, touches the skin. The vibration amplitude slowly increases until the person feels the vibration. The amplitude (in microns) at that point is the VPT. Higher than normal VPT is an indication of neuropathy.

The Mobile-Enabled Diabetic Foot Analyzer (mDFA) is a portable neuropathy screening device that provides quantitative information about a diabetic patient’s touch sensation in the foot. It connects wirelessly to a mobile phone or tablet, which can record sensation levels and track changes over time.

The m-DFA evaluates a person’s nerve function by determining the Vibration Perception Threshold (VPT) at a given point. VPT is defined as the lowest intensity of vibration that a person is able to feel at the application location. A probe, which vibrates at a fixed frequency of ~100 Hz, touches the skin. The vibration amplitude slowly increases until the person feels the vibration. The amplitude (in microns) at that point is the VPT. Higher than normal VPT is an indication of neuropathy.

acknowledgements

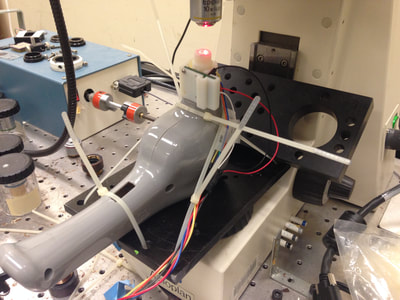

During my master's I was part of the Laboratory for Human and Machine Haptics (TouchLab) in the Research Lab of Electronics at MIT. I worked under the guidance of Dr. Mandayam A. Srinivasan and Dr. Mohan Thanikachalam of Tufts School of Medicine and Agada Hospital. Michael Fragoso, an undergraduate researcher, helped prototype a portion of the electronics. The project was funded by the MIT Tata Center for Technology and Design.

links/media

- Tata Center project description

- Interview with the Tata Center

- Article in the Hindu Newspaper

I designed every part of the system, including mechanical hardware, electrical system and PCB, software, analysis, and the human subject study to validate the device. The key components of the project were:

- Interviewed doctors, community health workers, hospital technicians, and patients to understand their needs and preferences

- Selected appropriate actuator and sensor that best satisfied functional requirements and quantitative design parameters

- Managed project budget and made sourcing and purchasing decisions for lab equipment and materials

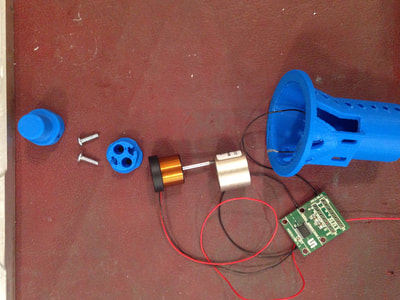

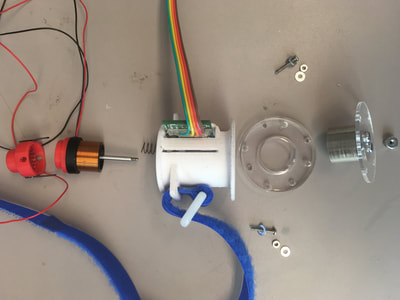

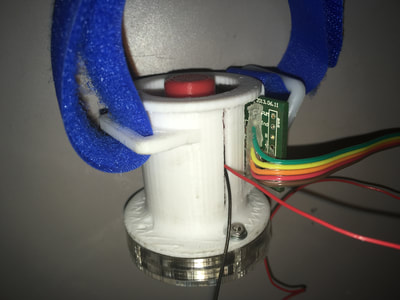

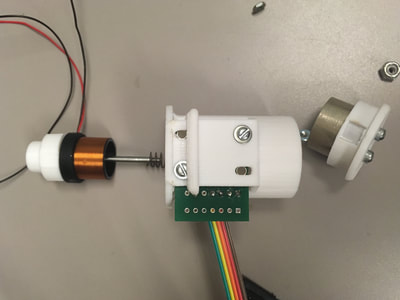

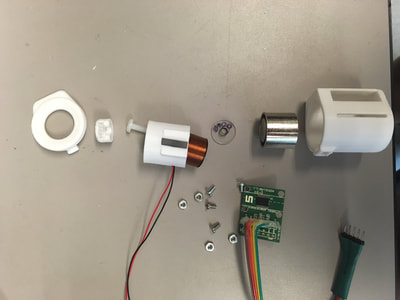

- Used an iterative design and prototyping process to converge on a final design that met or exceeded all requirements and was suitable for manufacture and assembly. Fabricated six identical devices to be field-tested in hospital and rural settings in India

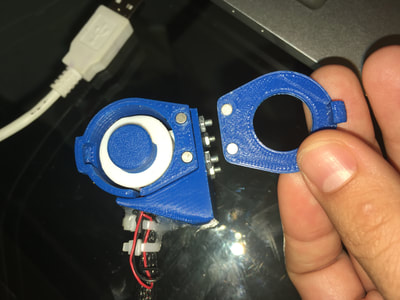

- Designed a novel voice coil suspension flexure assembly that satisfied calculated stiffness and DOF needs. Optimized material and dimensions using FEA, and experimentally verified that the design met requirements

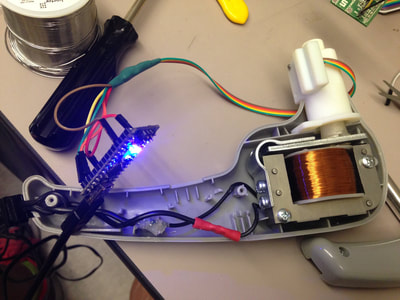

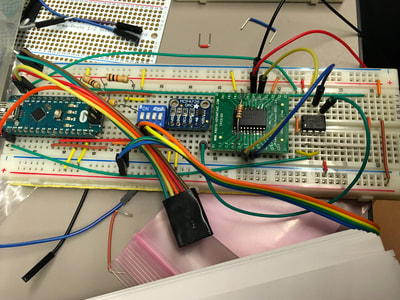

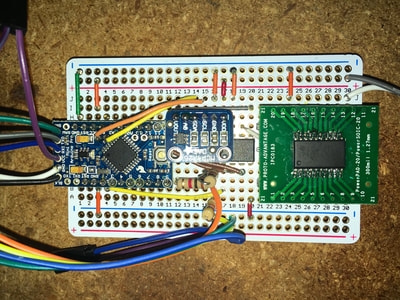

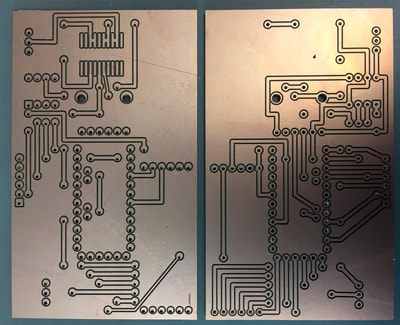

- Designed and fabricated a PCB to control voice coil vibration and measure amplitude with sub-micron precision

- Programmed an Arduino microcontroller to interface with electronics using SPI, I2C, and Bluetooth

- Developed mobile and desktop apps using Python and App Inventor for user interface, data acquisition, and data processing

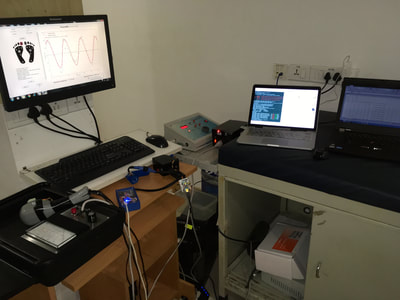

- Planned and coordinated a study to validate the device against existing gold standards. Trained and supervised a team of engineers and technicians at Agada Hospital in Tamil Nadu, India to collect data on a range of diabetic and normal patients

(Hover over images to see captions, click to enlarge.)